Features:

1. More worry-free: CCD visual positioning system, 360-degree product placement, no fixtures, no mechanical positioning,

2. More labor-saving: the assembly line circulates intermittently, and the dispensing machine basically does not need special personnel to take care of it.

3. Higher precision: Equipped with a screw volume metering precision dispensing valve to ensure a more concentrated color temperature distribution;

4. More extensive: This system can meet the requirements of large quantities and diverse occasions;

5. Smarter: the needle can be cleaned automatically during the dispensing process;

6. More stable: Grinding grade dispensing manipulator, quieter movement, higher precision

Applications:

Photovoltaic panels, craft gifts COB COG sealant, SMT circuit boards, 3C, sensor sealants, switch connectors, breakers, radiators, semiconductors, LEDCOB, electronics, electrical appliances, window grilles, hanging tablets, RFID smart cards

Online Consultation

Online Consultation

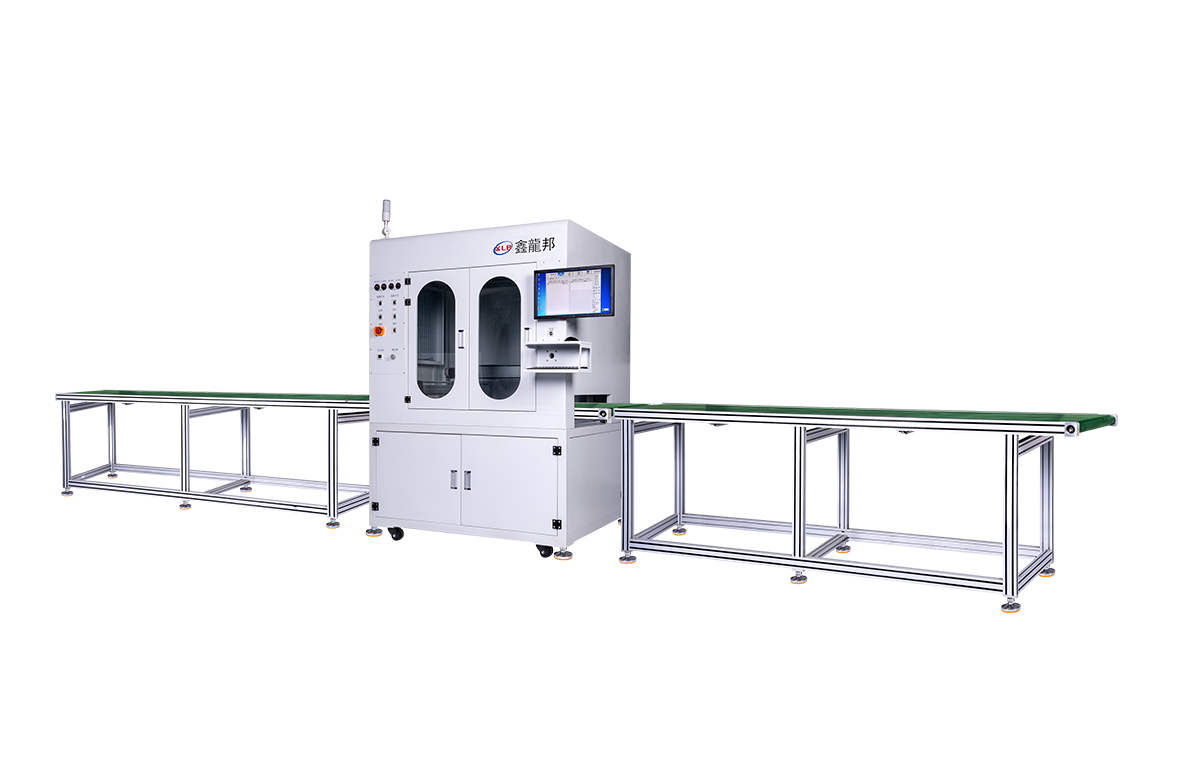

| Model | PV551AL |

| visual scanning method | panoramic recognition |

| Glue volume control method | Volume metering pneumatic type/jet valve/piezoelectric valve/double liquid filling valve |

| Equipped with the number of dispensing valves | 1 set |

| Applicable bracket size (L×W) | 500mm × 500mm |

| Work desk platform | 1 |

| positioning accuracy | ±0.03mm/300 |

| input power | AC 220V 1500W |

| Working temperature | 5~40℃ |

| working environment humidity | 20~90% |

| Supply air pressure | ≥0.5 MPa |

| Dimensions | 1300×1300×1980mm (except assembly line) |

| body weight | 600KG |