Features:

1. More efficient: a cup can be stirred in 3-5 minutes

2. Smarter: unbalanced glue weight, excessive vibration alarm

3. More quiet: synchronous wheel + imported synchronous belt drive

4. More uniform: automatic revolution, 3000 rpm spindle drive

5. Low cost of use: two-year warranty

6. Long service life: brand accessories

Applications:

LED phosphor, cleaning agent, medicine, epoxy resin, solder paste, silver glue, silica gel, aluminum paste, ink, paint

Online Consultation

Online Consultation

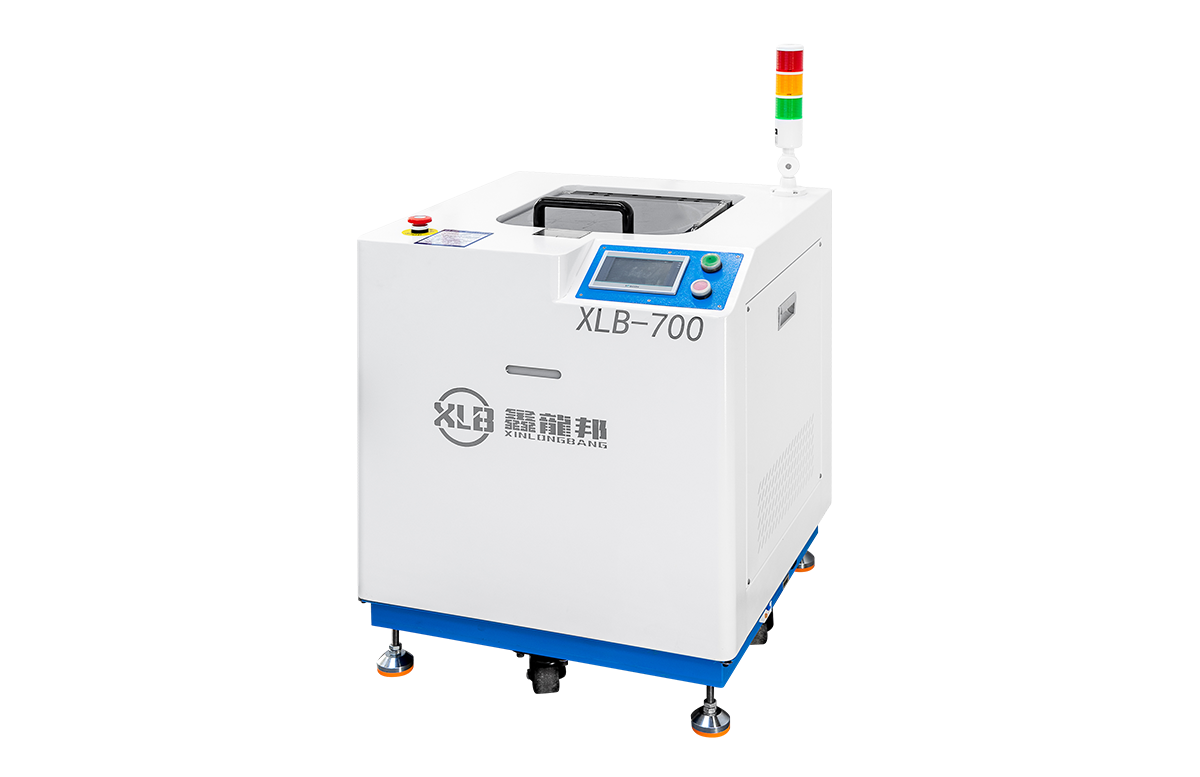

| Model | XLB-700 |

| Standard container: | 700mL*2 |

| Maximum throughput: | 350mL*2 |

| Syringe throughput | 5CC-50CC, plus 500CC bracket |

| Revolution: | The public rotation ratio is fixed at 1:0.8 |

| Maximum speed: | 2800rpm |

| Vacuum pump power | 750W |

| Vacuum speed | 20m³/H |

| Vacuum pressure: | 0.1Kpa |

| transfer method: | Silent synchronous belt drive |

| Control System: | Chinese interface touch screen operation |

| Noise: | ≦40dB |

| Safety: | Excessive vibration alarm |

| Work completed alarm prompt | |

| emergency stop button | |

| door support | |

| door safety lock | |

| Voltage supply: | AC220-240V |

| power: | Standby: 50W Maximum power consumption: 1.5KW |

| physical dimension: | 640*640*810(mm) |

| Machine weight: | 180kg (subject to the actual product) |

| Standard configuration: | 6 700mL plastic cups, 1 set of power cord and counterweight. |

| Precautions: | Syringe fixture needs to be customized |